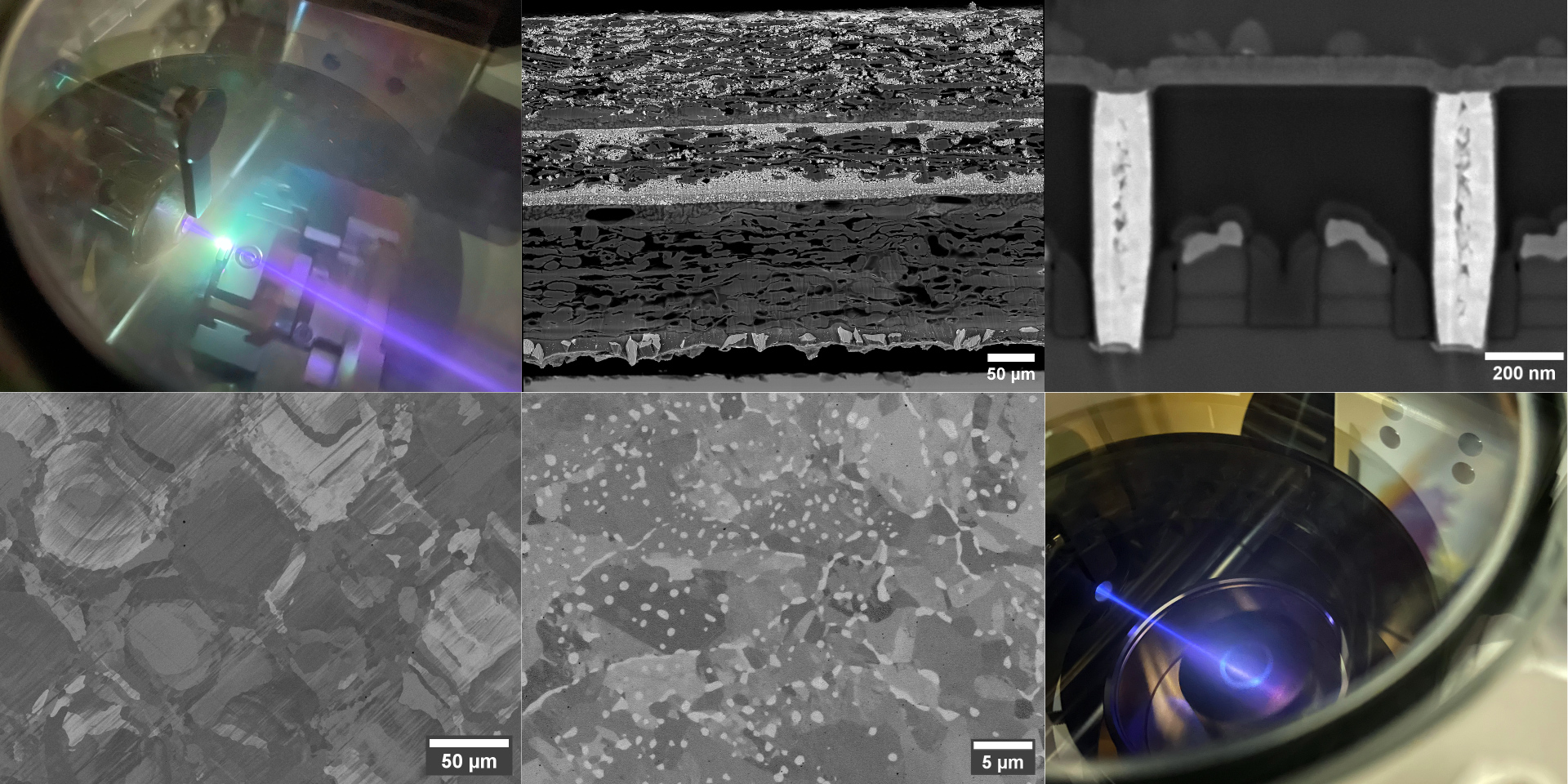

Broad Ion Beam mill

Hitachi ArBlade IM5000 CTC

for sample cross-sections and surface ion polishing

The Hitachi IM5000 Broad ion beam mill is a multi-use sample preparation tool, enabling cross-sectioning and surface polishing. Cross-sections can be prepared in various widths, from 1 mm up to 8 mm, producing mechanically undisturbed view into the material structure. Layer thicknesses and composition can then be evaluated using e.g. SEM-EDS analysis. The cryogenic add-on allows processing of heat-sensitive materials, such as polymers or metals with low melting points.

Surface polishing after mechanical preparation is also possible. In this flatmilling mode, the ion beam incidence angle can be freely selected to provide selective sputtering for relief generation, or surface smoothing and cleaning for EBSD analysis by removing the outer layers of the material, damaged by mechanical pre-polishing.

Trinocular stereo microscope allows visual process observation and recording. Direct operation via built-in touchscreen allows generation of two-stage processes. External control software also available for creation of more complex processing sequences.

For more information, contact Ermei Mäkilä.

Specifications:

- Ion beam acceleration voltages from 0.1 kV to 8 kV

- Argon processing gas

- Intermittent beam operation possible

- Cross-sections

- maximum sample size: 20 × 12 × 7 mm (width, depth, height)

- selectable swing angle for curtain effect minimization

- processing width adjustable from 1 to 8 mm using motorized wide area milling holder

- cryogenic processing with temperature control from 0 to -100 °C

- high beam tolerance tungsten carbide masks

- Surface polishing

- maximum sample size: 50 × 25 mm (diameter, height)

- maximum milling area diameter: 32 mm

- freely adjustable beam incidence angle (0 – 90°)

For more information, contact Ermei Mäkilä.