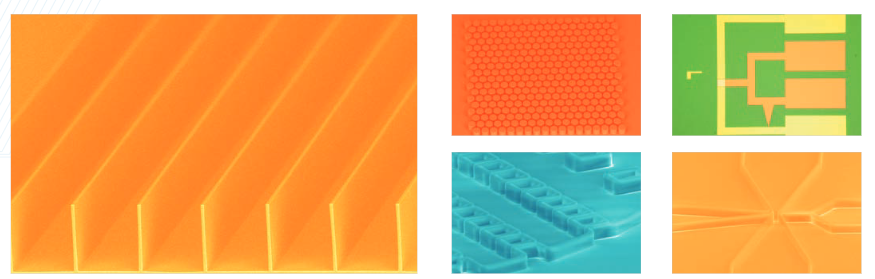

Maskless lithography laser writer

Dilase 250 tabletop laser lithography system

Photolithography is used to pattern samples for e.g. electrical measurements. Typically the photoresist in first spinned on the sample and then exposed to UV-light through a mask, which covers the parts of the films that are kept. Maskless lithography uses a focused laser beam for the UV-exposure removing the need for the mask and allowing fast development of patterns. Otherwise the process is Then the photoresist is developed and the exposed parts removed. The film is etched e.g. either wet chemical etching or ion beam etching and finally the developed photoresist is removed.

For more information, contact Hannu Huhtinen.

Specifications:

- Multilevel alignment accuracy < 1 µm

- Minimum feature size ~ 1 µm

- Up to 4″ wafers and 5″ × 5″ square substrates

For more information, contact Hannu Huhtinen.